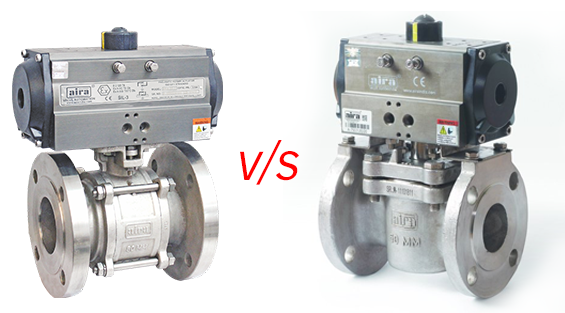

How are Plug Valves Different from Ball Valves

Valves are mechanical devices which control the flow of a fluid within a system or a process. These essential components in pieces of machinery or equipment come in various types, the two of which are – Plug Valves and Ball Valves. Both are quite similar as one has evolved from the other, but there are some obvious differences too.

Let’s look at the top three most important differences between ball valves and plug valves:

Also Check: Best 6 Pneumatic Ball Valves

The Difference in Principle:

Plug Valve

In the case of the plug valve, you have a conical plug and not a ball; and you have the body surface formed due to the conical pressure exerted by the tight sealing or packing of the gap between the plug as well as the body. Plug valve being simple, is also often economical because it usually has handles exposed outside at the end instead of bonnets.

Ball Valve

The ball valve is actually evolved from the plug valve. That’s why you will find the same 90-degree rotation operation in both of them. But, just like the name, the ball valve has a spherical disc with a hollow center. This disc rotates by 90 degrees on the axis of the channel and cuts off the flow of the fluid at the inlet and outlet by closing them off using it’s spherical edges – like a ball.

Difference in Application

When it comes to performance, you will find the plug valve providing a better sealing effect with more torque and a smaller diameter, owing to its larger sealing surface. That’s why, in terms of cutting, they are slightly better than the ball valves.

Plug Valve

When it comes to performance, you will find the plug valve providing a better sealing effect with more torque and a smaller diameter, owing to its larger sealing surface. That’s why, in terms of cutting, they are slightly better than the ball valves.

Ball Valve

Not as good as the plug valves, when it comes to sealing application, the ball valve is pretty ideal when you want to switch pipeline medium. Plus, with continually-evolving sealing technology, ball valves aren’t completely out of the game.

Difference in Cost

Plug Valve

In the case of the plug valve, you have the “plug” completely covered by the bushing, that makes the valve body as well as the plug free from wear. So, all you need to do is replace the bushing and the top seal to repair and update the valve, to meet the long-term service requirements of 300℃. Plus, it uses MONEL, INCONEL, HAST alloy and such other special materials to get built. It easily has a price advantage over the ball valve.

Ball Valve

The considerable competitive advantage of having a bushing that the plug valve has over a hard-sealed metal ball valve, especially around a temperature of 300°, makes the latter more expensive.

As you know, we are Valve Manufacturer in India since 1990. We offer a complete solution in Automation Valve Industry and always ready to accept challenges.